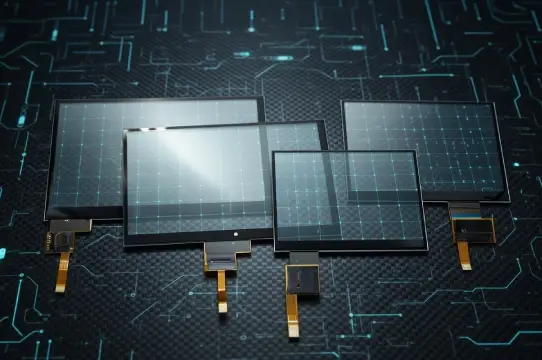

TFT-LCDs are widely used technological products, required for display quality in everything from smartphones and tablets to commercial displays.

In LCD display manufacturing, thinning the LCD glass panel is a crucial process. It helps optimize the design and performance of the finished display. As a professional manufacturer of commercial displays, we will discuss this process today.

Whether you are an engineer, designer, or an enthusiast in the field of TFT-LCDs, we hope this article will provide you with some assistance and help you better understand its role in LCD display manufacturing.

Why Does The Glass Back Panel Of TFT-LCD Need To Be Thinned?

TFT-LCD glass panels are manufactured in large-format form using CF color filter substrates and Array TFT substrates. The manufacturing principle involves coating these substrates with sealant, injecting liquid crystal, and then assembling them in a vacuum environment.

Because different LCD glass panels have different sizes, we categorize the production lines for large-format TFT-LCD panels into different "generation lines."

Generally, the higher the generation line, the larger the panel size, and the more efficient it is in terms of cutting and utilization in large-size display equipment.

Due to the relatively large size of the glass substrates themselves, to ensure the yield rate and manufacturability of the LCD display panel front-end manufacturing process, the glass substrates used for large-format panels are generally quite thick. These substrates are typically 1.2mm, 1.0mm, 0.8mm, or 0.6mm thick.

However, using this thickness directly in the finished product would be very bulky, so the thickness must be reduced according to the specific thickness requirements of the product.

Thinning LCD glass panels offers two main advantages: Thinner and lighter design: Reduced thickness allows for more compact devices, freeing up space for increased battery capacity and extended battery life.

Improved display performance: Especially in L0 black screen mode, thinning reduces light leakage. Based on the principle of photoelasticity, with constant photoelasticity coefficient and stress, thinning reduces the phase difference R, thus improving black screen light leakage.

Large LCD Glass Panel Thinning Process

The thinning process for large-format LCD glass panels is not as simple as it seems. A lot of preparatory work is required before the actual operation. The two most crucial steps are panel cutting and thickness reduction.

However, whether or not cutting the large-format glass panel is necessary depends on the supplier's substrate size and the compatibility of the thinning equipment. If the manufacturer's equipment capabilities are limited and do not support the thinning and polishing of larger glass panels, then cutting the large-format LCD glass panel is necessary first.

The core process of large-format LCD glass panel thinning includes incoming material inspection, cutting (optional), UV sealing, pre-thinning cleaning, etching thinning (including pretreatment), thickness measurement, and post-thinning cleaning.

Among these, UV sealing and glass etching thinning (pretreatment) are the key steps, which I will describe in detail below.

UV Sealant For LCD Glass

Before chemically treating the LCD glass panel, the edges and sides of the glass panel must be sealed with UV-curable adhesive to prevent the etching solution from seeping in and corroding the circuitry during the subsequent chemical etching and thinning process.

UV-curable adhesives for glass sealing can be mainly divided into two types according to the sealing method:

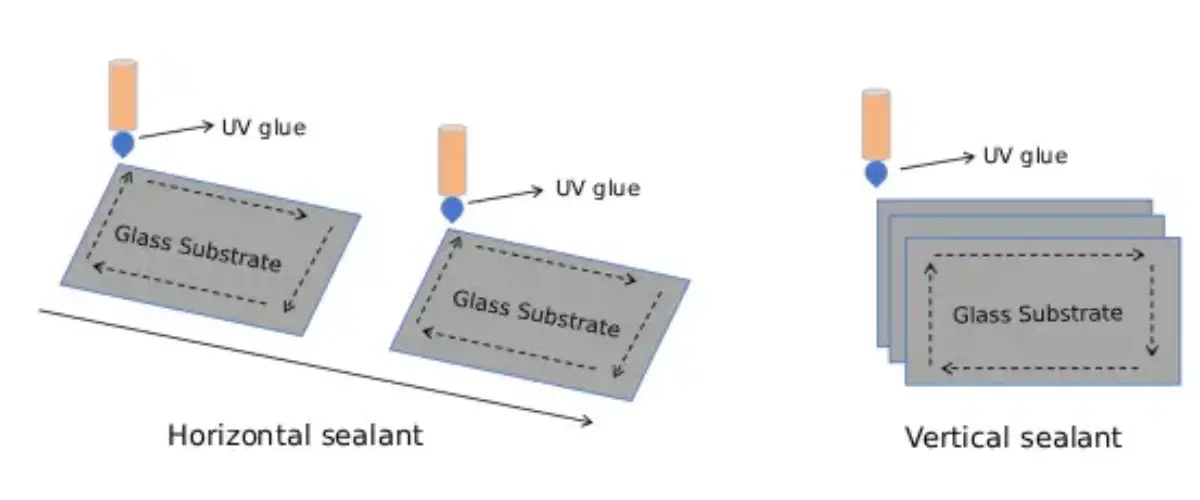

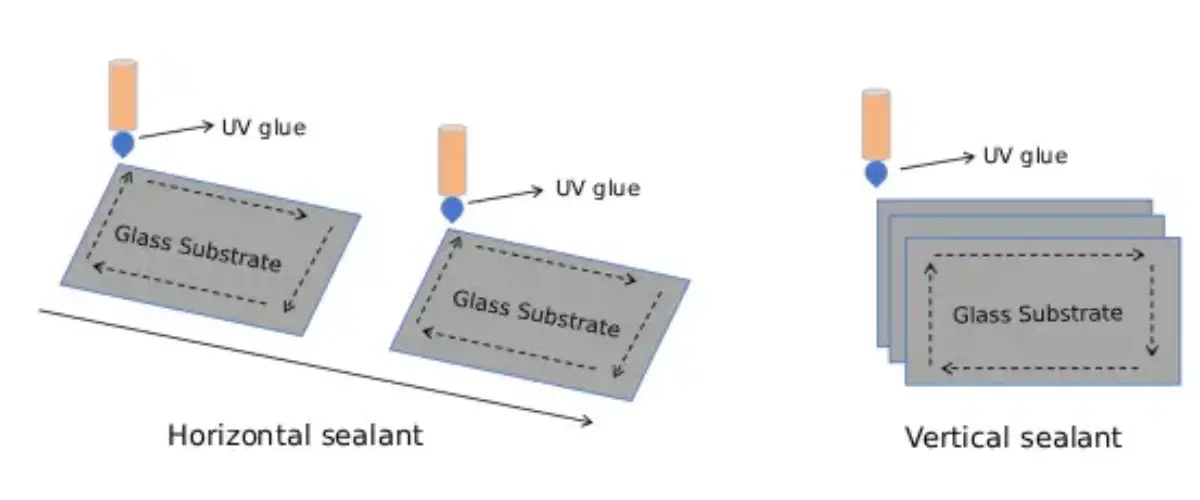

*Horizontal Sealing: After applying UV adhesive to all four sides of the large LCD glass panel, all four sides are simultaneously cured under UV light using a sheet-type curing method.

*Vertical Sealing: Unlike horizontal sealing, vertical sealing does not seal all four sides of the large LCD glass panel at once. Instead, it seals only one direction at a time, then cures it, and this process is repeated.

LCD Glass Etching To Reduce Thickness

LCD glass etching and thinning mainly consists of two steps: surface pretreatment and etching thinning.

a. Surface Pretreatment: Pretreatment for glass etching and thinning primarily involves micro-processing of scratches, pits, bumps, and dirt on the surface of large-panel LCD glass panels to improve the yield rate during the etching and thinning process.

Generally, the etching rate during the LCD glass etching and thinning pretreatment process is 0.4~0.6 μm/min, and the pretreatment time is approximately 25~40 minutes.

b. Etching Thinning: In the thinning process of large-format LCD glass panels, two main thinning techniques are used: the most common is chemical etching, supplemented by physical polishing.

Physical polishing is not an essential step in the thinning process. Its use depends on factors such as the surface finish of the large-format LCD glass panel after chemical etching, the structure of the LCD panel (square, teardrop, blind hole, etc.), and the material of the LCD glass panel.

The most common principle of chemical etching is to use hydrofluoric acid (HF) or a mixture containing hydrofluoric acid (HF) to react chemically (etch) the surface of the LCD glass panel, thus etching it to achieve the goal of thinning the large-format LCD glass panel.

Four Common Methods For Thinning Large-format LCD Glass Panels

Besides the content mentioned above, there are actually different ways to chemically etch large-format LCD glass panels. This chapter will mainly discuss four ways to thin large-format LCD glass panels.

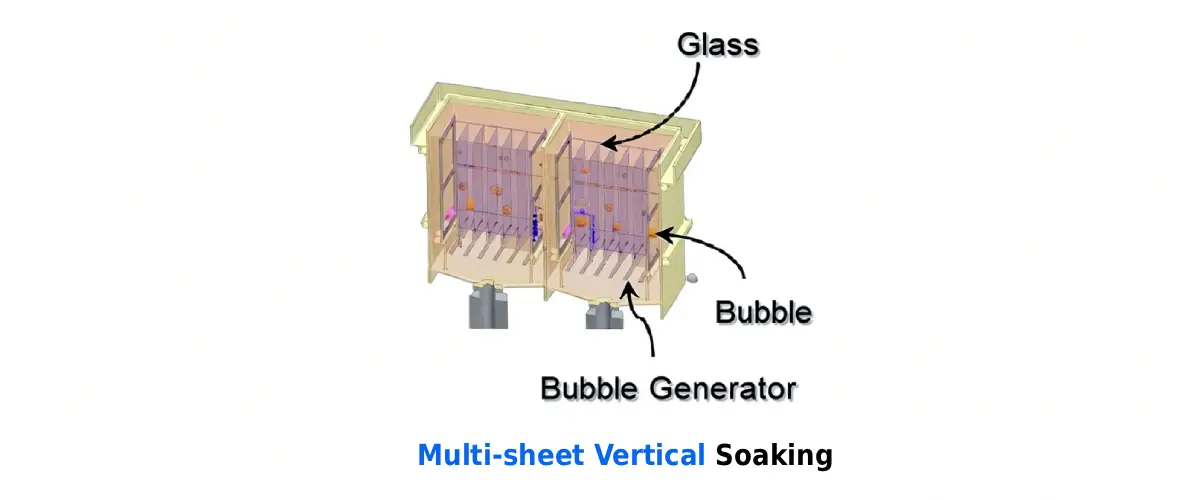

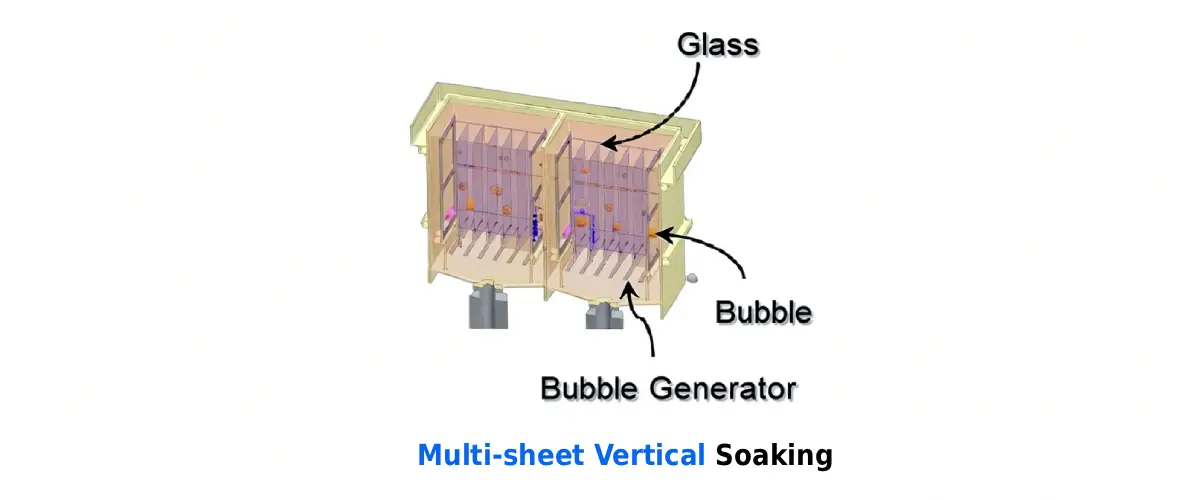

Multi-sheet Vertical Immersion Thinning

Advantages: Can process multiple sheets of glass simultaneously; simple equipment; high efficiency; currently one of the most widely used mainstream processes.

Disadvantages: Etching byproducts (such as glass flakes) easily adhere to the surface; thickness uniformity and surface quality are relatively average.

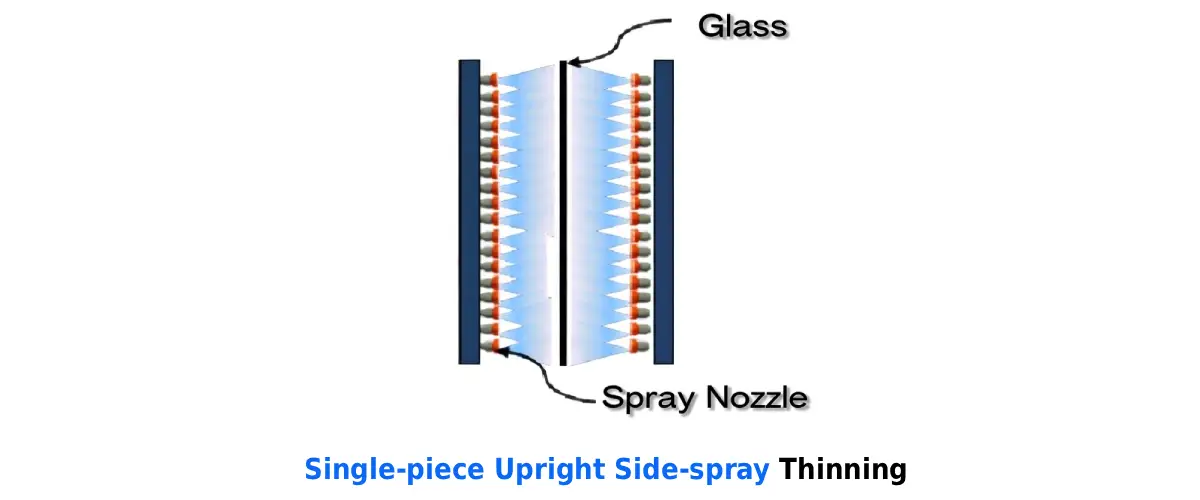

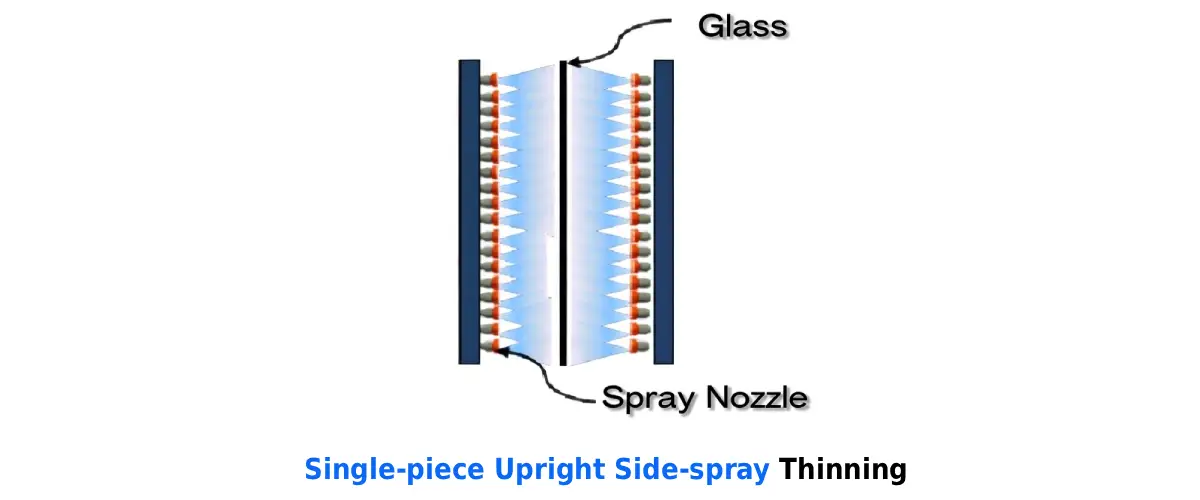

Single-piece Vertical Side-spray Thinning

Advantages: Asymmetric etching can be achieved by adjusting the spray volume on both sides; the acid flow carries away the glass frit, resulting in good surface quality and thickness uniformity.

Disadvantages: Only one piece can be processed at a time, leading to low efficiency; the glass surface is susceptible to pressure-induced pitting; equipment maintenance is complex.

Multi-piece Vertical Top-spray Thinning

Advantages: Processes multiple pieces at once, higher efficiency than side-spray; good acid flow, less glass frit adhesion, excellent surface uniformity, and is one of the mainstream processes.

Disadvantages: Cannot achieve differentiated etching on both sides; the glass surface still has the risk of stress-induced pitting; equipment maintenance is relatively cumbersome.

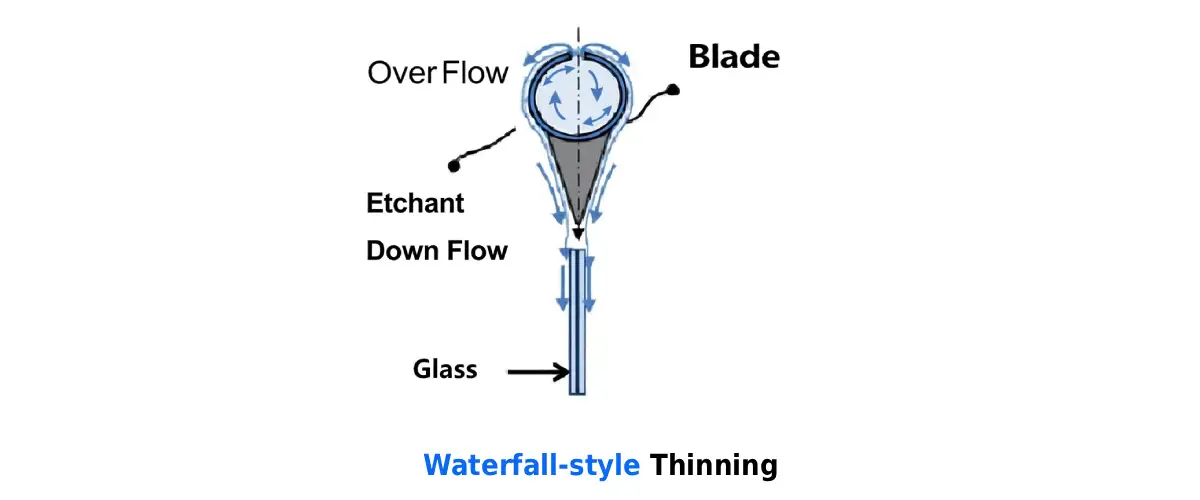

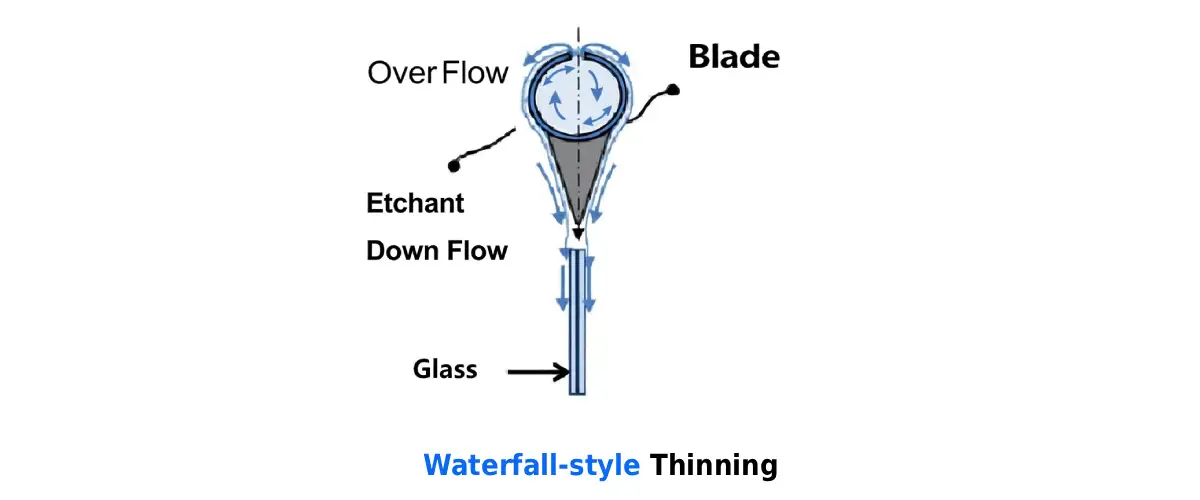

Waterfall-style Thinning

Advantages: Minimal pressure on the glass, fewer surface pits, and higher quality; lower acid consumption, suitable for applications with high surface finish requirements.

Disadvantages: Can only be processed on a single sheet, resulting in lower production efficiency.

Conclusion

The thinning process of large-format LCD glass panels is directly linked to the thickness, weight, and visual effect of the final finished product. Manufacturers should choose the appropriate thinning method based on product structure, thickness requirements, surface quality standards, and production capacity needs.

By continuously optimizing the thinning process, manufacturers can not only improve product performance but also maintain competitiveness in the market, bringing users lighter, thinner, and higher-quality display devices with superior display quality.

![]() Retail Digital Display Solution

Retail Digital Display Solution![]() Public Transportation Digital Signage Solution

Public Transportation Digital Signage Solution![]() Entertainment Digital Display Solution

Entertainment Digital Display Solution![]() Healthcare Digital Display Solutions

Healthcare Digital Display Solutions![]() Education Digital Signage Solutions

Education Digital Signage Solutions![]() Corporate Digital Display Solutions

Corporate Digital Display Solutions![]() Art Digital Display Solution

Art Digital Display Solution![]() Industrial Digital Display Solutions

Industrial Digital Display Solutions![]() Hotel Digital Signage Solutions

Hotel Digital Signage Solutions![]() Outdoor Digital Signage Solutions

Outdoor Digital Signage Solutions