Before the warehouse upgrade, Tizelius reported that employees were extremely busy but inefficient, with average order processing times reaching several hours and frequent instances of incorrect or missing shipments. Employees were constantly stressed, resulting in a very unfriendly work environment.

After deploying digital signage and undergoing a three-month trial period, warehouse data analysis showed that real-time information guidance optimized picking routes, increasing order processing speed by 40%, reducing unnecessary employee movement within the warehouse by over 60%, boosting daily orders to 1000, and lowering the error rate to 5%. This enabled Tizelius to collaborate with more clients and handle greater business volume.

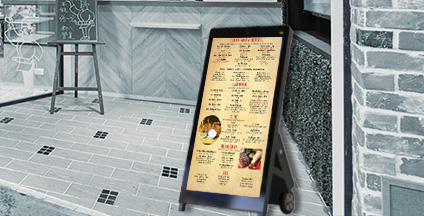

![]() Retail Digital Display Solution

Retail Digital Display Solution![]() Public Transportation Digital Signage Solution

Public Transportation Digital Signage Solution![]() Entertainment Digital Display Solution

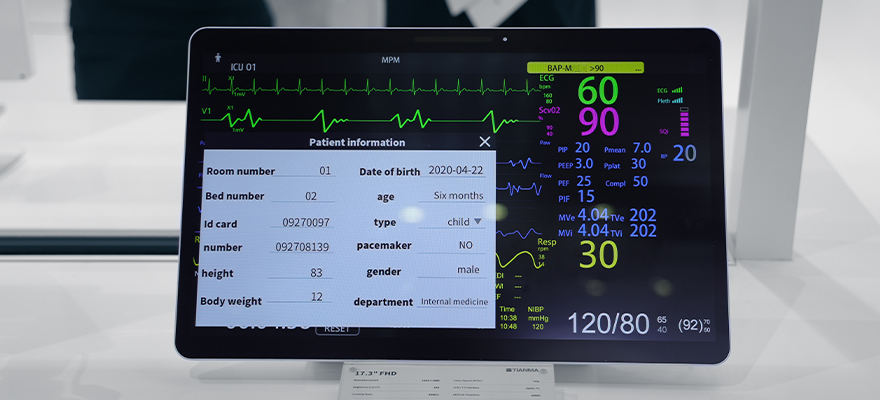

Entertainment Digital Display Solution![]() Healthcare Digital Display Solutions

Healthcare Digital Display Solutions![]() Education Digital Signage Solutions

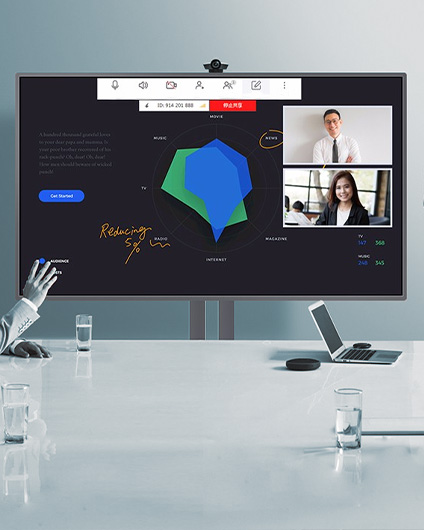

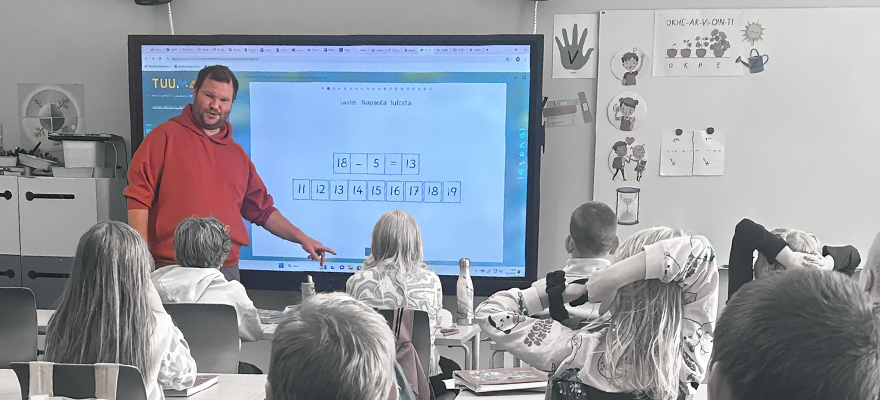

Education Digital Signage Solutions![]() Corporate Digital Display Solutions

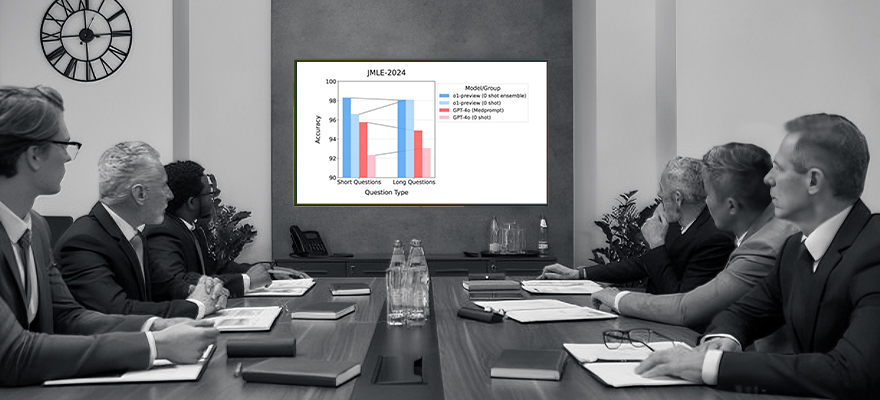

Corporate Digital Display Solutions![]() Art Digital Display Solution

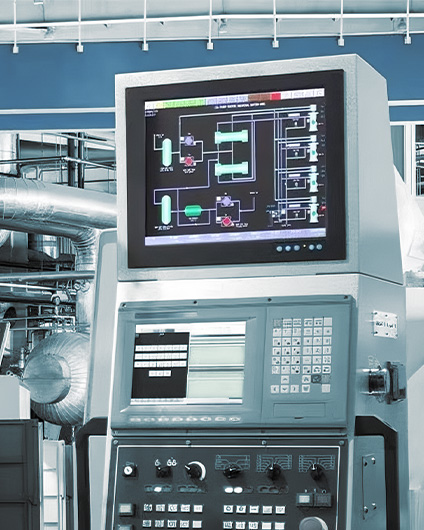

Art Digital Display Solution![]() Industrial Digital Display Solutions

Industrial Digital Display Solutions![]() Hotel Digital Signage Solutions

Hotel Digital Signage Solutions![]() Outdoor Digital Signage Solutions

Outdoor Digital Signage Solutions