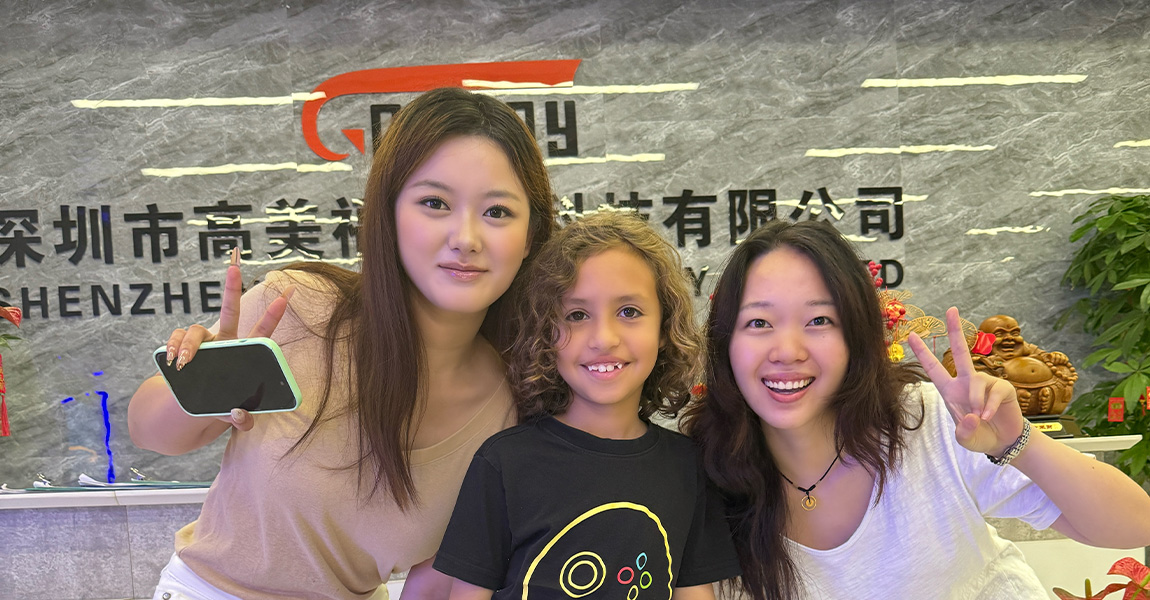

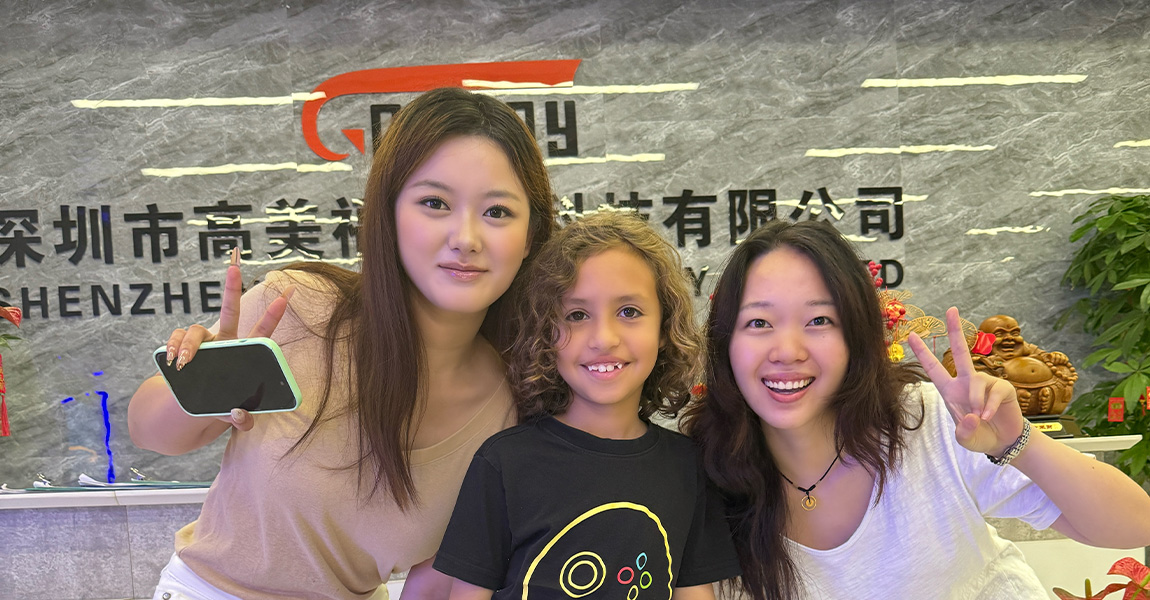

On July 2, 2025, our customer Julián from Colombia visited Gomany. The exchange focused on business cooperation. Julián gained an in-depth understanding of the production process and products. This exchange was not only an opportunity for business cooperation, but also an exchange meeting on digital display.

Our sales manager Rachel welcomed Julián to the company at around 9 o'clock in the morning. After arriving, Julián and our CEO Liao Bin had a detailed discussion on a series of products and technologies. Then, Julián expressed his desire to learn more about our production processes and products.

Visiting OC Panel Cutting Workshop

We took our LCD glass cutting workshop as the first stop for the visit. This is the first step in the production of square LCD display and bar type display. Advanced cutting equipment and cutting technology can ensure that we can customize LCD panels of various sizes and proportions. Julián is very interested in this process. He would ask questions to our sales manager Rachel from time to time to learn about every detail of the cutting process and how to flexibly adjust the cutting plan according to different order requirements.

Visiting The Assembly Workshop

Following the manufacturing process, we came to the assembly workshop, which is an important link to ensure the quality and reliability of the display. Julián observed the systematic workflow and the strict quality control measures implemented at each stage, and gained a deep understanding of the high production standards we maintain.

He noticed that from the cleaning of parts to the final assembly, each step has strict operating specifications and quality inspection standards. What impressed him even more was our meticulous management of the dust-free environment, including air filtration, temperature and humidity control, and personnel dress standards, which ensured the high-quality output of the product, which made Julián feel satisfied and at ease.

Visiting The Aging Test Workshop

The visit continued to the LCD screen aging test workshop, which is a key step in verifying the durability and service life of the product. By conducting rigorous aging tests on the equipment under various conditions, we are able to identify and resolve any potential problems before the product is delivered to customers.

Julián asked about the specific process and standards of the aging test, and learned how we simulate different usage environments and conditions and conduct comprehensive inspections on photos. Our technicians explained to him in detail the temperature, humidity, brightness and other parameter settings for the aging test, as well as how to monitor and record the various performance indicators of the equipment during long-term testing.

Visit The Sample Room

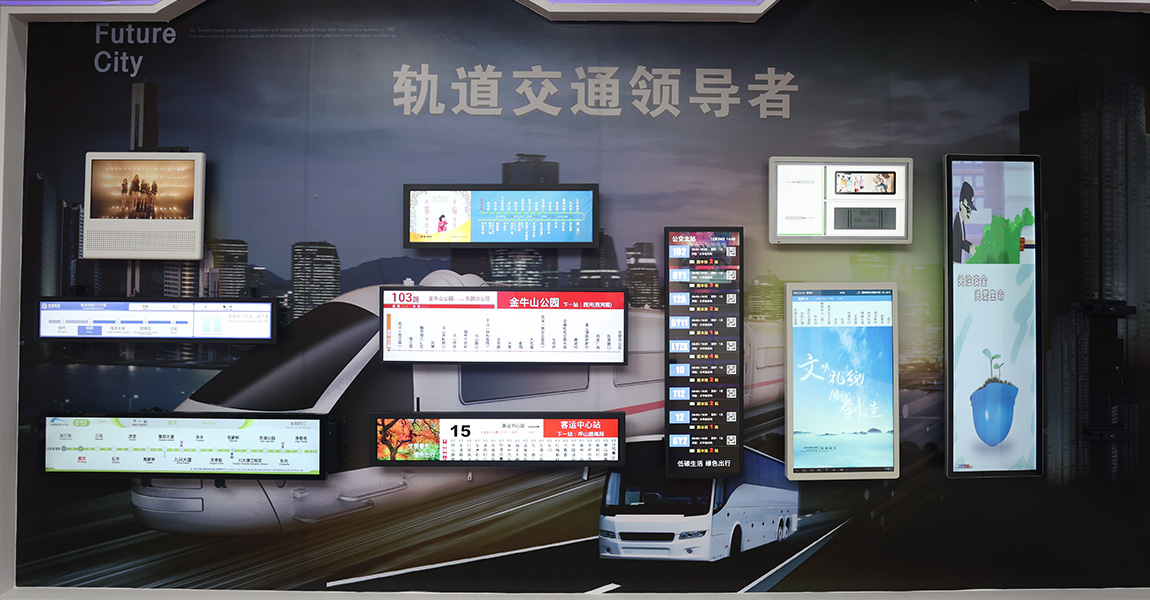

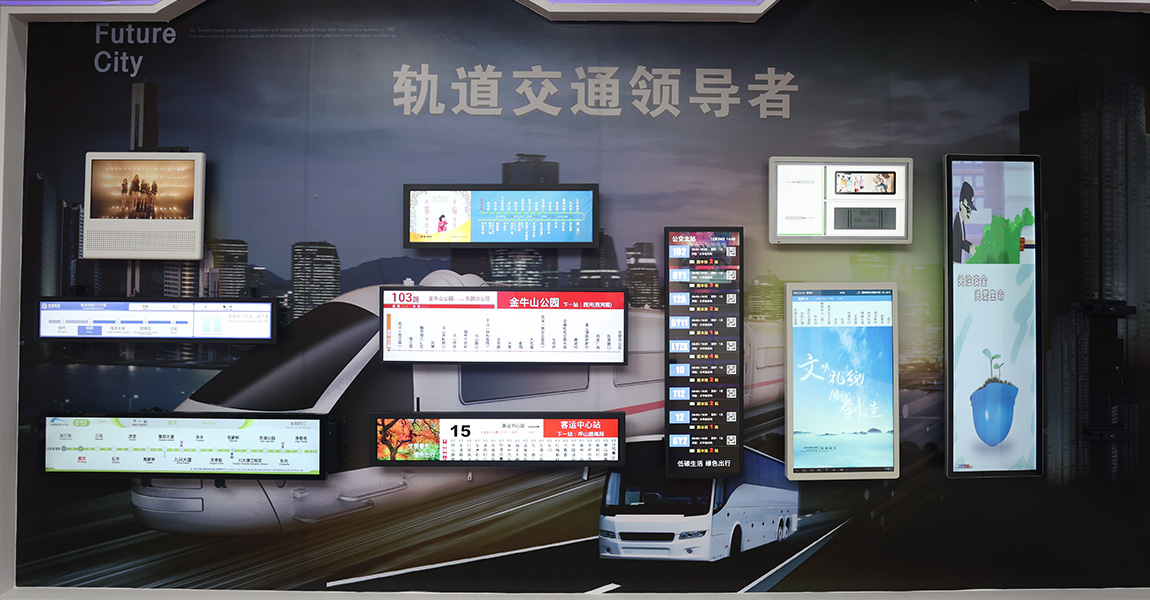

After visiting some important production processes, Julián asked to visit our products. We took him to our sample room, where we displayed digital display devices for various solutions. Among so many products, our ultrathin double sided digital signage attracted Julián's attention.

This is a new product developed by Gomany in April. Its slim appearance and ability to display dynamic content on both sides make it an ideal solution for various commercial scenarios. Julián carefully observed the appearance and functions of this product, asked about the technical details and application scenarios. After thinking for a while, the two sides jointly discussed the possibility of customizing products for these market needs, including the appearance design and compatibility with other devices.

Communication And Outlook

Throughout the visit, mutual respect and a shared passion for innovation were evident. Julián’s insightful questions and keen observations reflected his deep understanding of the digital display industry. Our team was happy to share details about our technical capabilities, customization options, and success stories in different fields, further consolidating the foundation for potential partnerships.

At Gomany, we always warmly welcome customers from all over the world and explore opportunities for growth and innovation. If you are also interested in our digital display solutions or would like to arrange a visit to our facilities, please feel free to contact us. We are committed to helping companies fully tap the potential of digital displays.

![]() Retail Digital Display Solution

Retail Digital Display Solution![]() Public Transportation Digital Signage Solution

Public Transportation Digital Signage Solution![]() Entertainment Digital Display Solution

Entertainment Digital Display Solution![]() Healthcare Digital Display Solutions

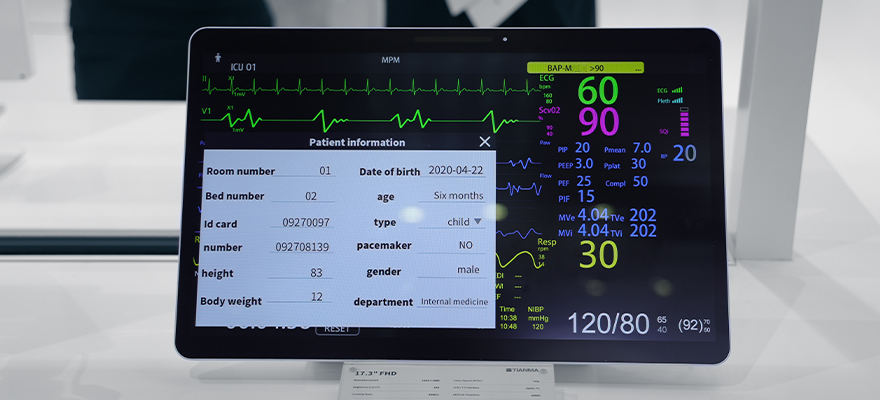

Healthcare Digital Display Solutions![]() Education Digital Signage Solutions

Education Digital Signage Solutions![]() Corporate Digital Display Solutions

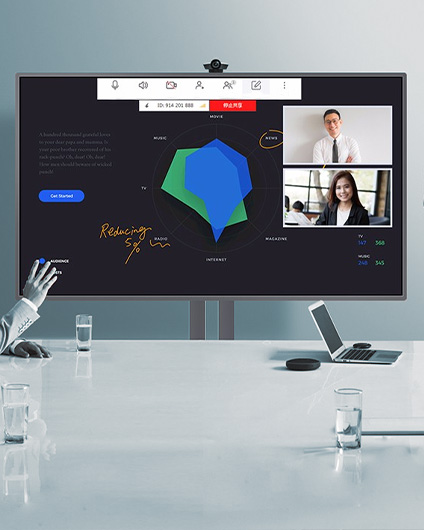

Corporate Digital Display Solutions![]() Art Digital Display Solution

Art Digital Display Solution![]() Industrial Digital Display Solutions

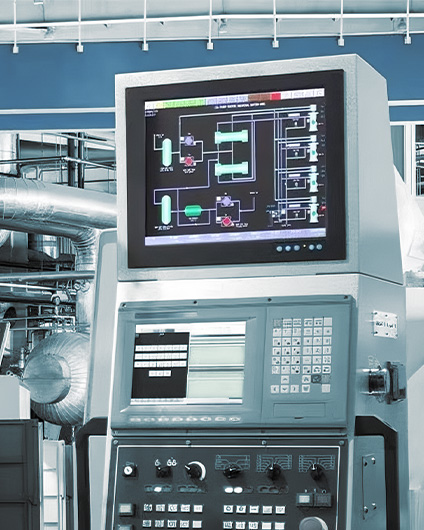

Industrial Digital Display Solutions![]() Hotel Digital Signage Solutions

Hotel Digital Signage Solutions![]() Outdoor Digital Signage Solutions

Outdoor Digital Signage Solutions